RENDERING SYSTEM

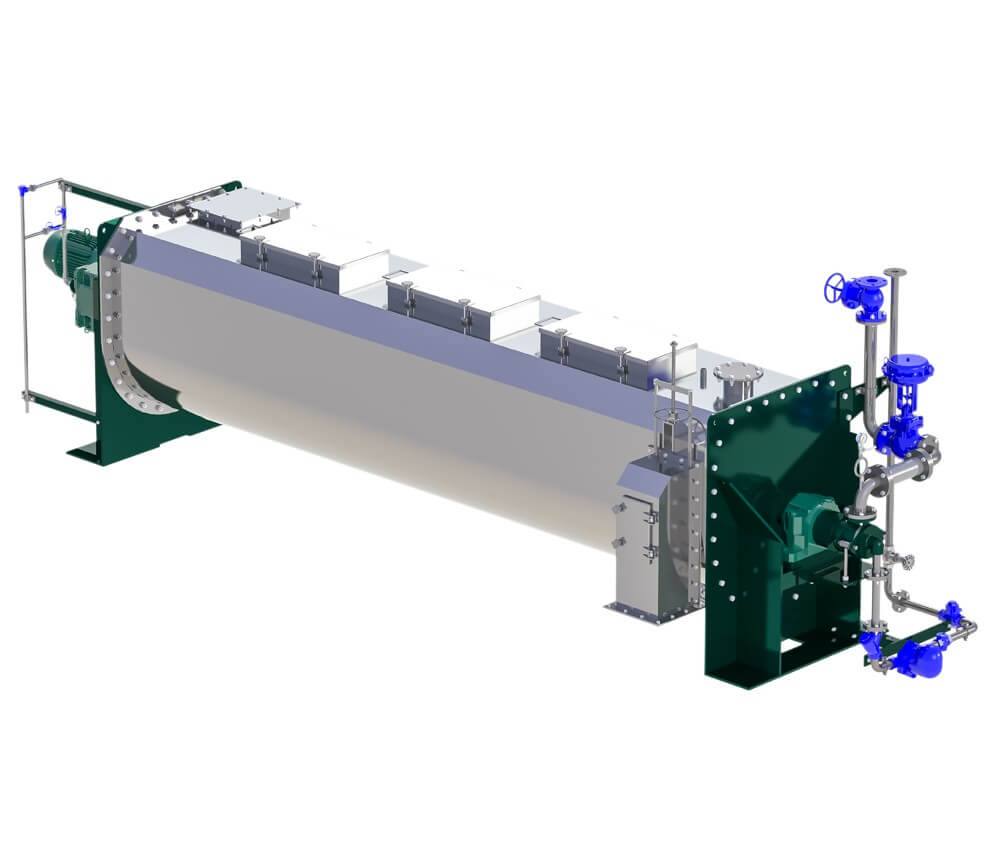

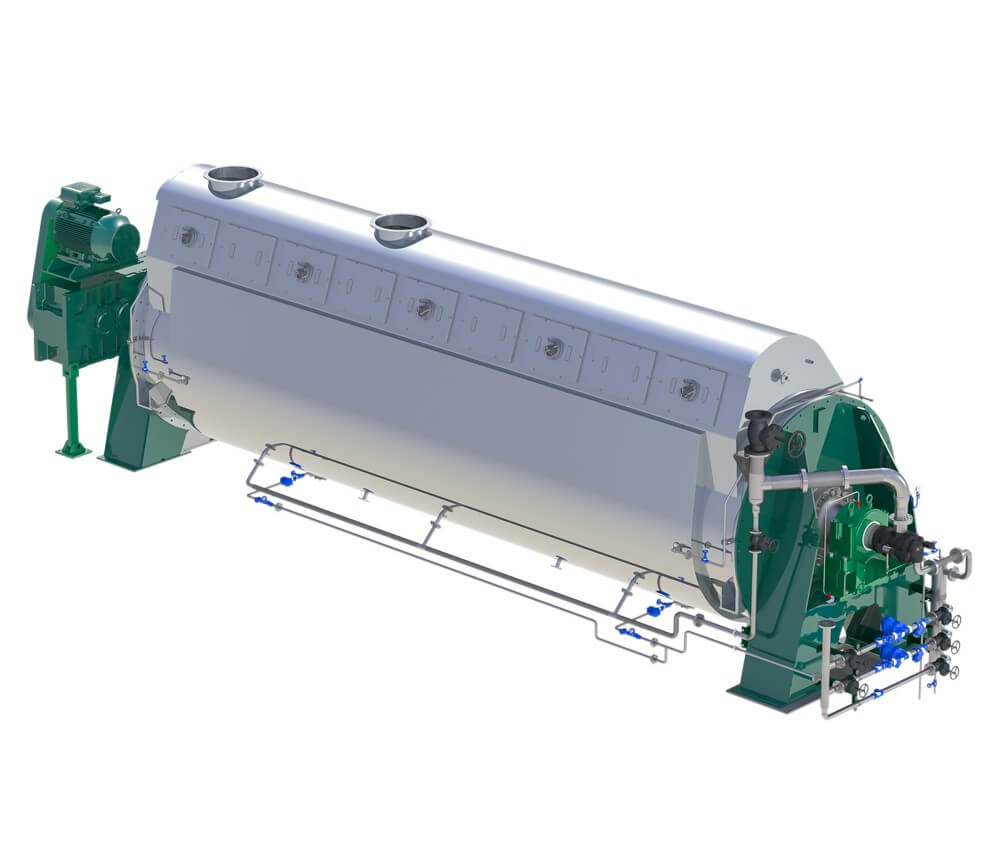

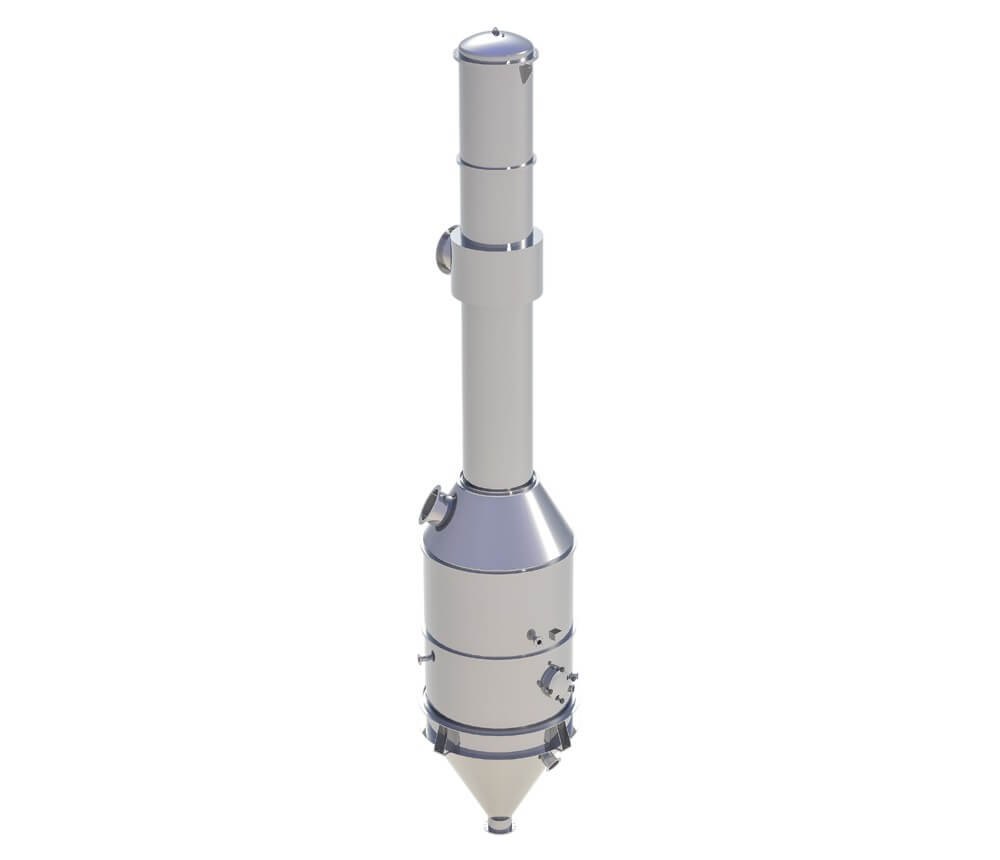

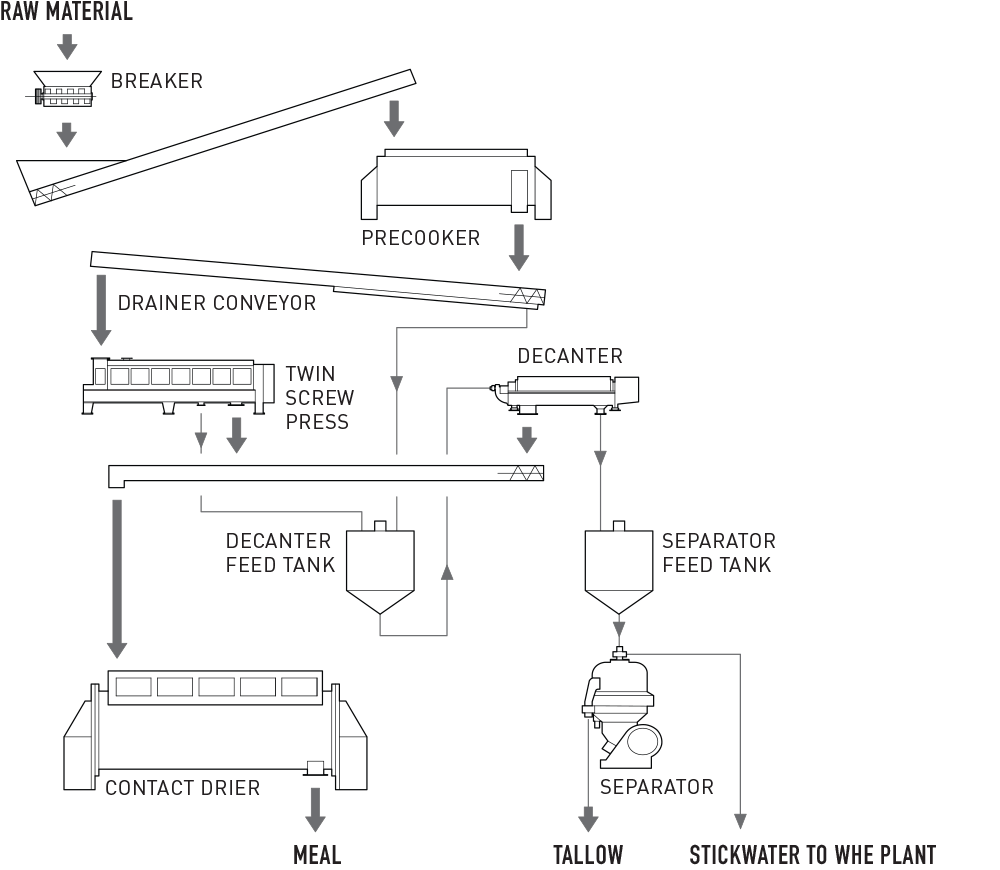

Press Dewatering System

The Rendertech Press Dewatering System (PDS) is a low-temperature wet rendering process suitable for plant raw material capacities of 5 tonne/hr and above. It produces high-quality end products, has low energy consumption and is simple to operate. When the system is fitted with a Rendertech Waste Heat Evaporator for stickwater recovery, the process is virtually ‘zero waste’, resulting in high product yield and low wastewater loads.