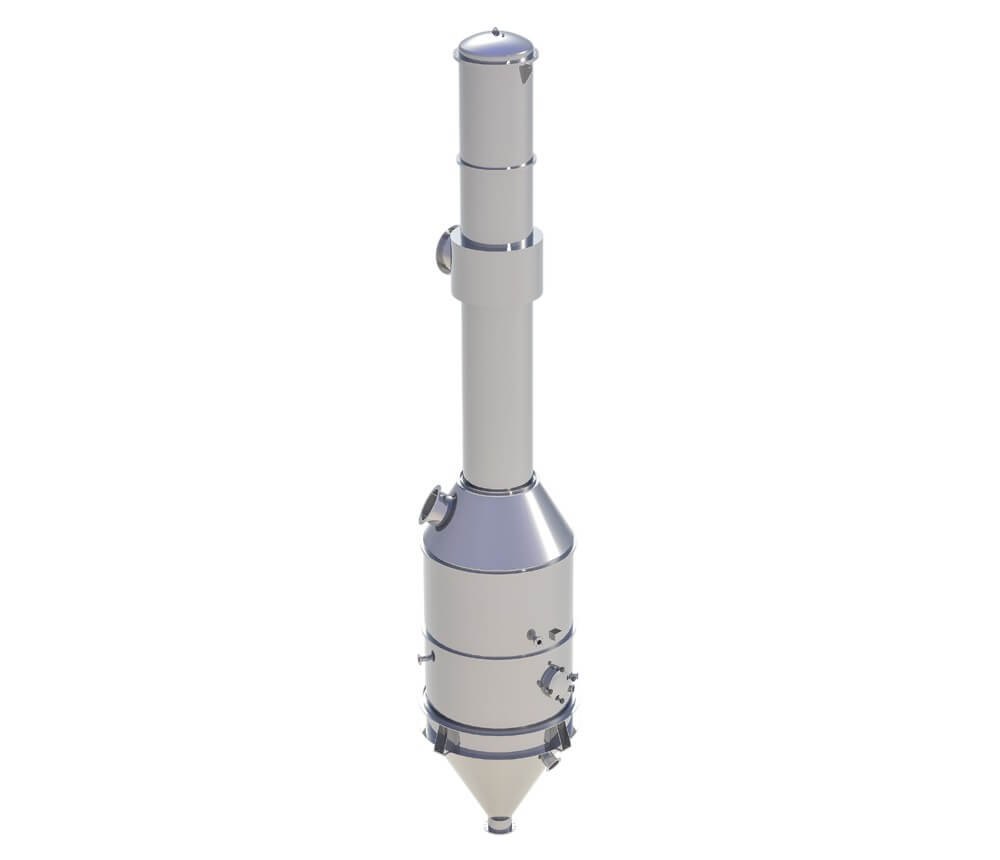

RENDERING EQUIPMENT

Waste Heat Evaporator

Rendertech evaporators, when used in rendering and fishmeal industries, maximise the return from raw materials, increase plant yields and eliminate a high-strength wastewater stream. Our Waste Heat Evaporator is a falling film-type evaporator operating under a vacuum. Simple and robust construction makes it very easy to operate and maintain.