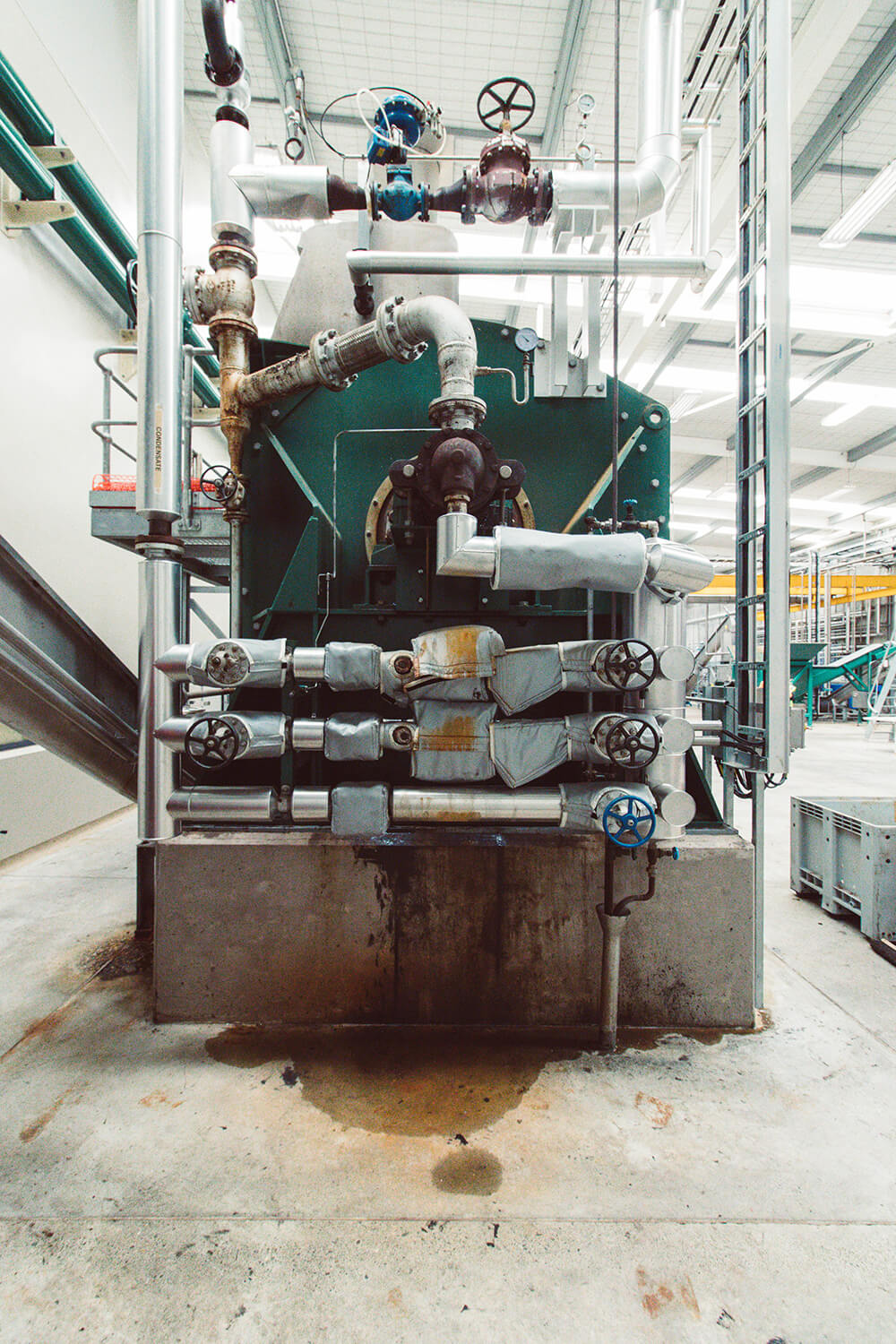

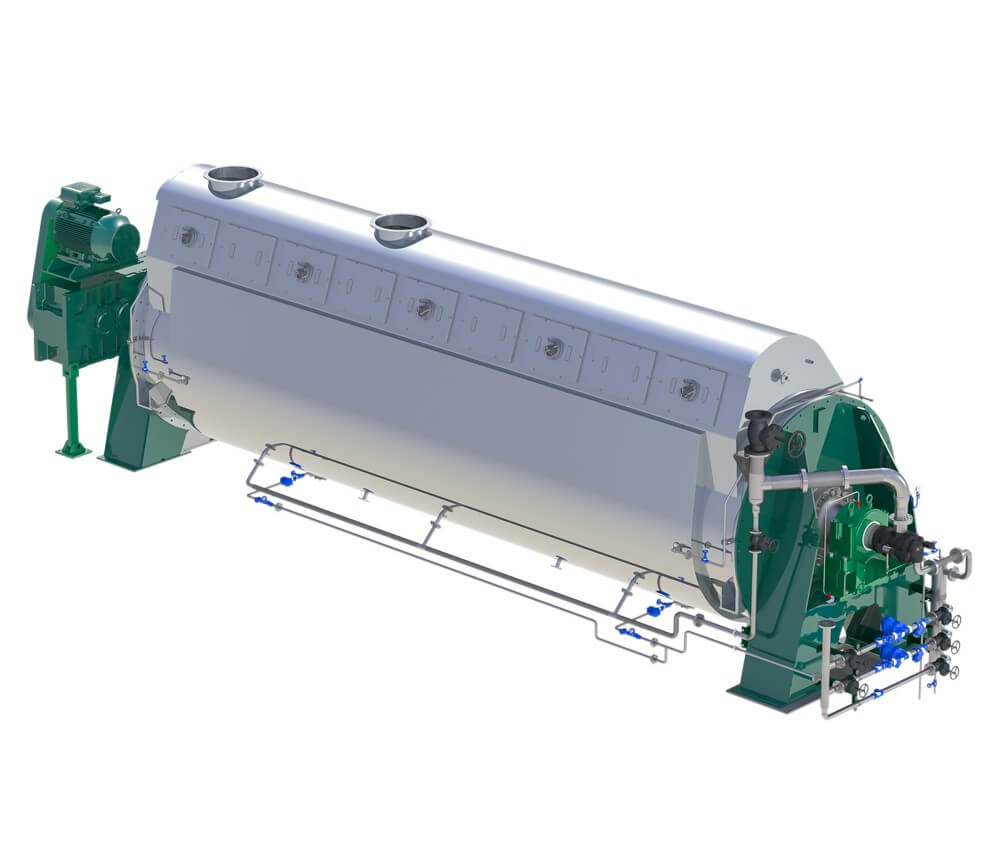

RENDERING EQUIPMENT

Contact Drier

The Rendertech Contact Drier (CD) is an indirect steam-heated, continuous drier for drying a variety of granular and fluid products. The construction consists of a horizontal shell with disc rotor for heating and transport of the product. The rotor comprises a tubular shaft carrying a number of steam-heated hollow discs. Fitted to the edge of the discs are agitator blades to transport the material along the drier. The design provides a large heating area in a compact footprint.