A Word from Our Clients

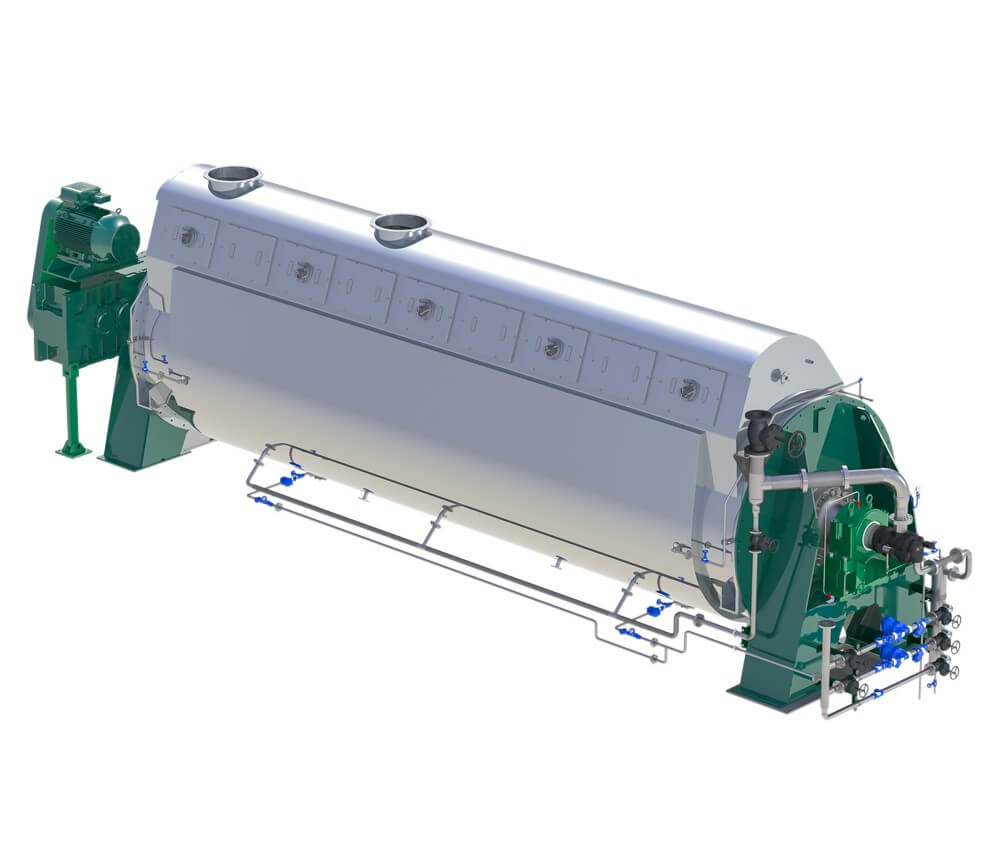

New Fish Meal Plant

'When we started a new product line in fish meal, we found our existing processing plant wasn’t fit for purpose. We needed a process

streamlined for fish to achieve a high-end product. Rendertech had the experience and expertise to achieve the quality we were after, with

good equipment design. They could also manufacture and install the plant quicker than anyone else, so our plant had the shortest downtime

possible. We’ve achieved all-round plant performance, with a high-quality fish meal, energy savings, and speed – we’ve increased from 2.5

tonnes an hour to 9.5 tonnes an hour with the new Rendertech plant, and reduced energy costs by 40%.'