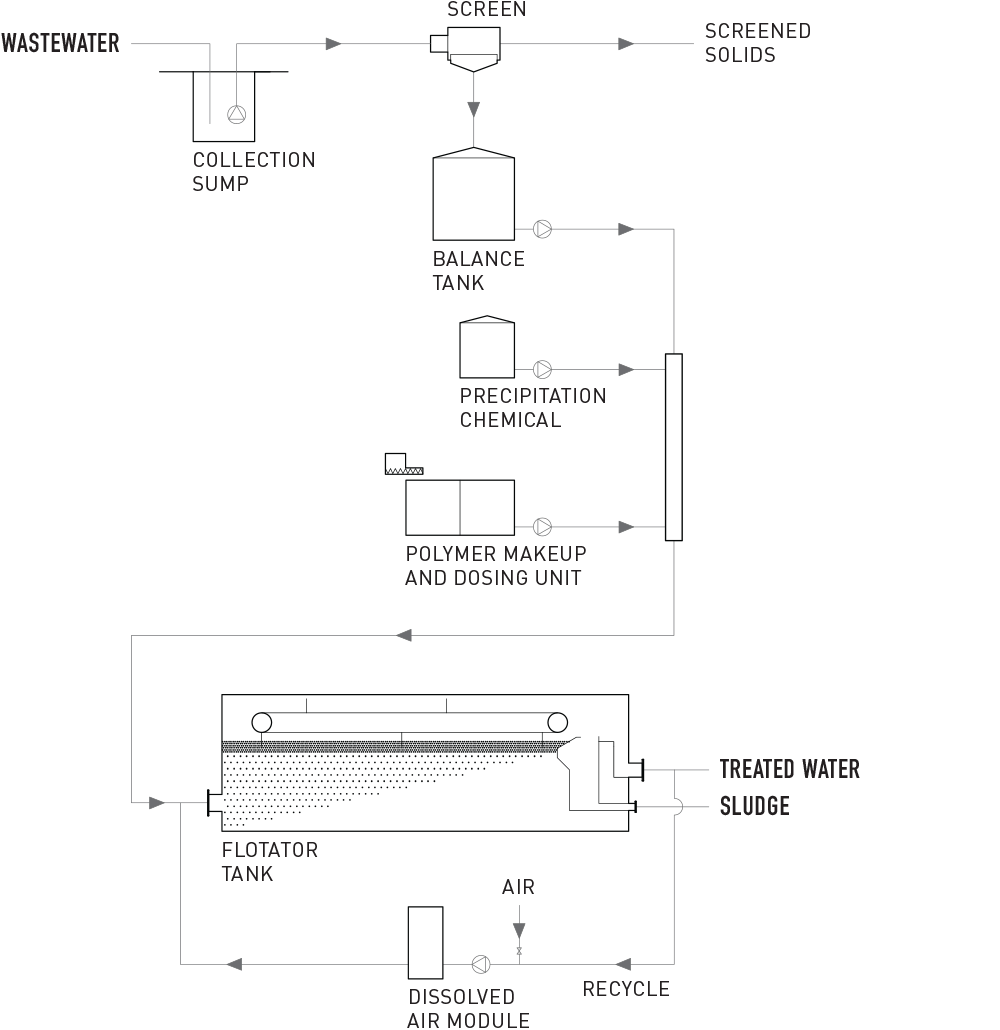

WASTEWATER TREATMENT SYSTEM

Dissolved Air Flotation (DAF) Plant

Rendertech Dissolved Air Flotation (DAF) plants provide the solution to many wastewater treatment problems. They are compact, efficient, simple to operate and economical to run. DAFs are used in a variety of industries as a primary method of wastewater treatment before discharge to sewer or irrigation, or for further treatment. Rendertech DAF plants are built using modular construction and can be supplied with chemical treatment modules to increase the degree of treatment.