WASTEWATER TREATMENT EQUIPMENT

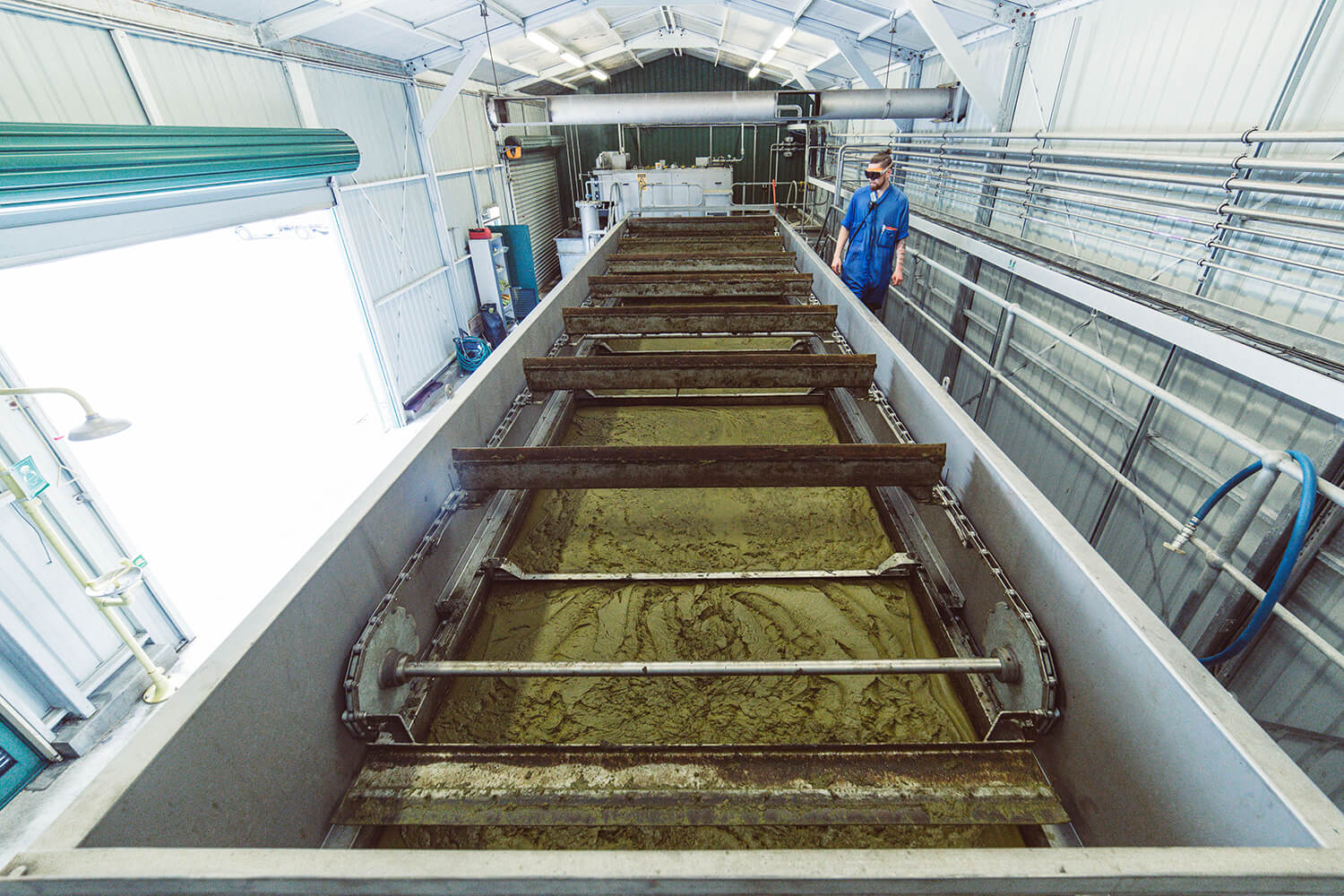

Dissolved Air Flotator

The Rendertech Dissolved Air Flotator is the central component of a Dissolved Air Flotation (DAF) system and they are normally sold together. It is constructed from stainless steel and comes in a standard range of sizes suitable for throughputs ranging from 10m³/hr to 250m³/hr. Its rectangular design provides laminar hydraulic flow and effective separation of solids from the liquid phase. Rendertech flotators are designed for unmanned operation and for producing a sludge with high solids content.