RENDERING SYSTEM

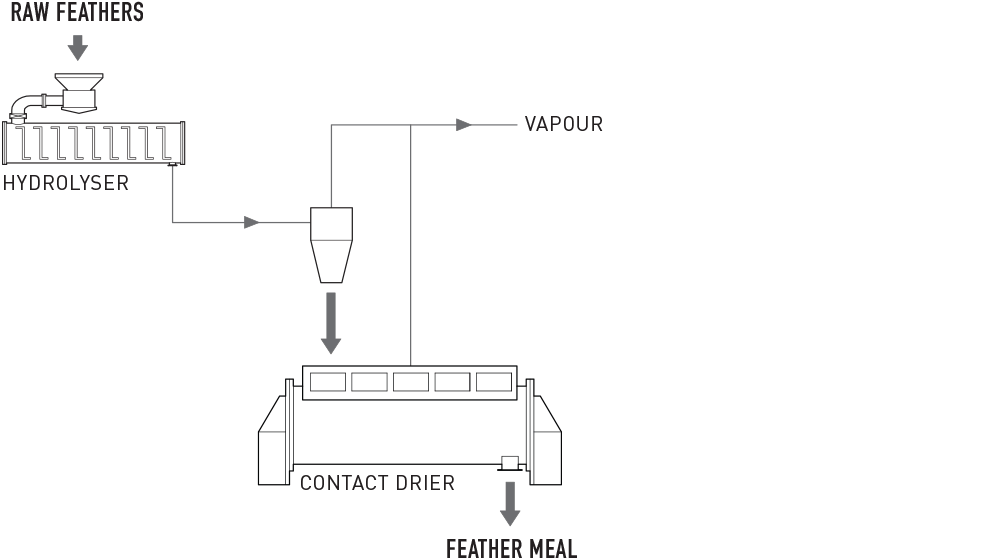

Continuous Feather Processing System

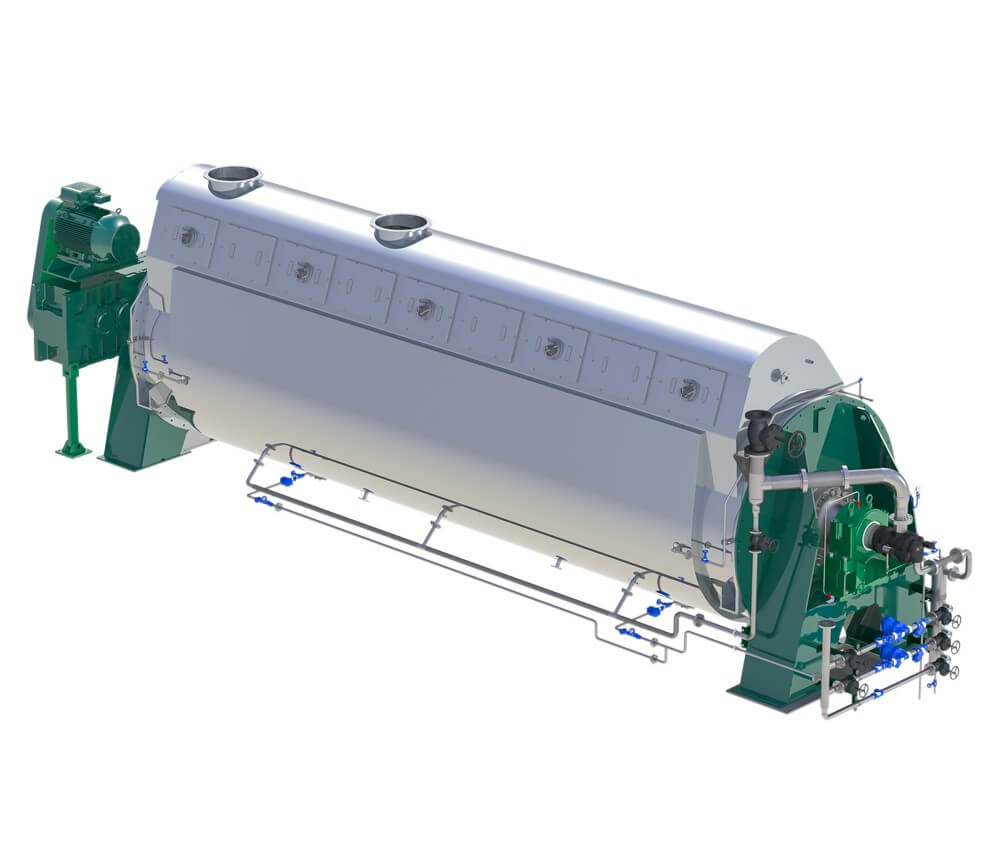

Feathers can be processed by the Rendertech Continuous Feather Processing System (CFPS) to produce a protein-rich meal with high digestibility. The continuous process is suitable for raw material capacities of 3 tonne/hr and above. The system, which is based on the Rendertech Continuous Feather Hydrolyser (CFH), produces high-quality feather meal, is energy efficient, and requires minimal labour to operate.