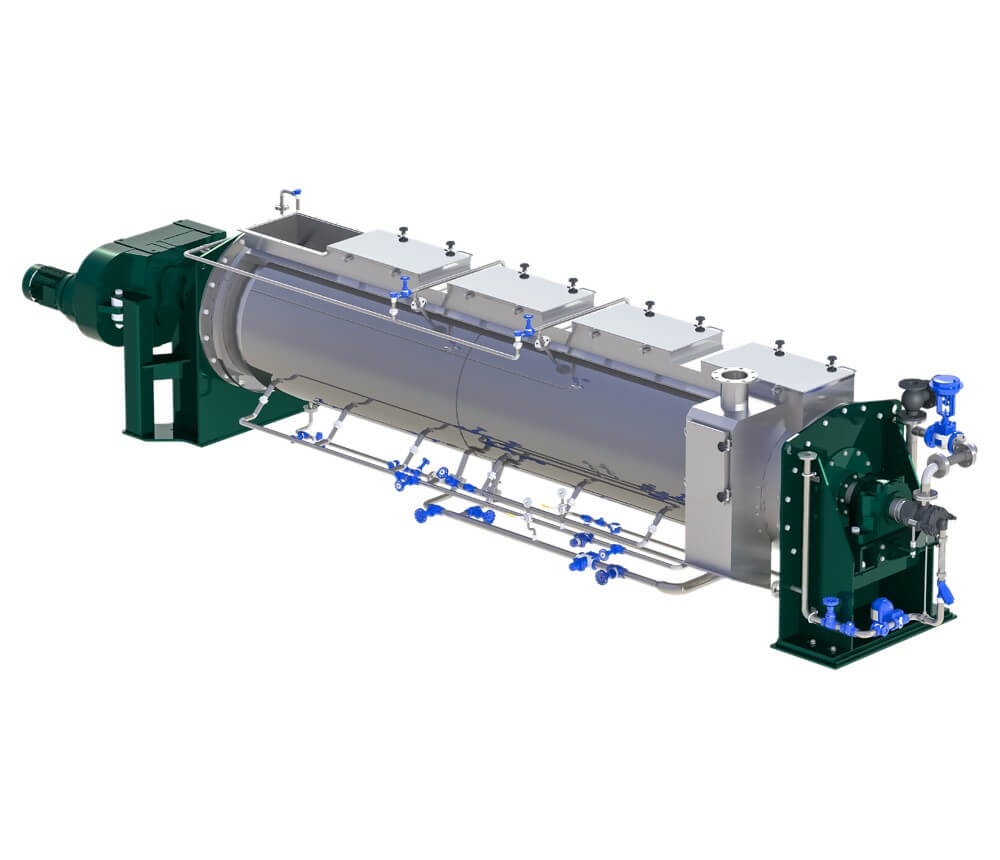

RENDERING EQUIPMENT

Fish Cooker

The Rendertech Fish Cooker is an indirect steam cooker used for processing high-yield raw materials. Its gentle screw rotor and even heating action ensure raw material structure is maintained during processing, leading to better pressing and better separation of solids, oil and water. The slow rotation speed makes the process very gentle on raw material.