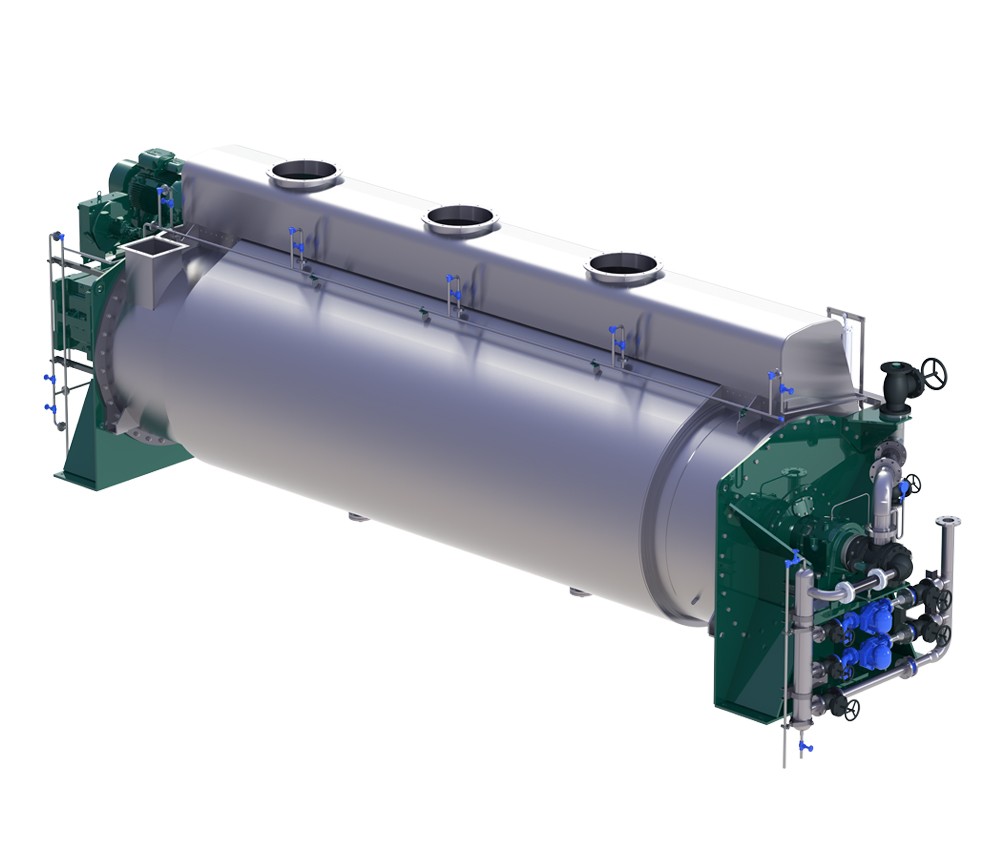

RENDERING EQUIPMENT

Continuous Cooker

The Rendertech Continuous Cooker is used as part of a continuous high-temperature rendering process. Product is heated indirectly with a series of hollow, steam-heated discs mounted on a central rotating shaft. This design gently heats the product with no harsh agitation to ensure efficient separation of the fat from the cake in subsequent processes.