O’Connor Beef Rendering Plant Upgrade, Victoria

Application: Beef Rendering Plant

Location: Pakenham, VIC Australia

G&K O’Connor is a family-owned business producing some of Australia’s finest beef. Situated in South-East Victoria, their operation

includes an on-site rendering plant, originally designed and established with Rendertech’s expertise in 1997.

With some areas of the plant nearing end of life, Rendertech was commissioned in 2022 to identify and implement an upgrade programme to ensure the plant was fit for the future and supported business growth aspirations.

THE CHALLENGE - AND OPPORTUNITY

The need to upgrade key parts of the rendering plant after 27 years of operation also presented an opportunity to take a more strategic long-term view, taking into account changes within G&K O’Connor’s business and operating environment.

Some key considerations shaped this review:

- A change in raw material input over time – larger, higher-fat animals had changed the raw material mix, with implications for the plant’s soft-fat processing.

- Future-proofing – business growth was creating capacity constraints that limited future expansion potential.

- Environmental factors – the existing equipment was not optimal for the plant’s raw material mix, resulting in elevated wastewater loadings and energy inefficiencies, so reducing the environmental footprint was a priority.

- Impact on operations – upgrades were carefully planned and scheduled to minimise disruption.

OUR SOLUTION

We worked with G&K O’Connor to systematically review current equipment and performance, and develop an upgrade plan to meet its business objectives. G&K O’Connor Sustainability and Innovation Manager Megan Williams says it was a highly collaborative process.

“We established a project group that included Rendertech and our operators. Getting everyone’s input was crucial for trouble-shooting and ensuring a successful upgrade process. Rendertech worked closely with our operators and on-site maintenance team to make sure the project ran smoothly and that our operators had ownership of the upgrades, as well as confidence in maintaining and troubleshooting it.”

The project involved a staged programme of upgrades:

- After 27 years of effective service, the original dryer was nearing the end of its operational life. To ensure continued reliability and to prepare for future business growth, it was replaced with a higher-capacity unit. The upgrade not only maintained essential operations but also positioned the plant to meet growing demand with increased operational and energy efficiency.

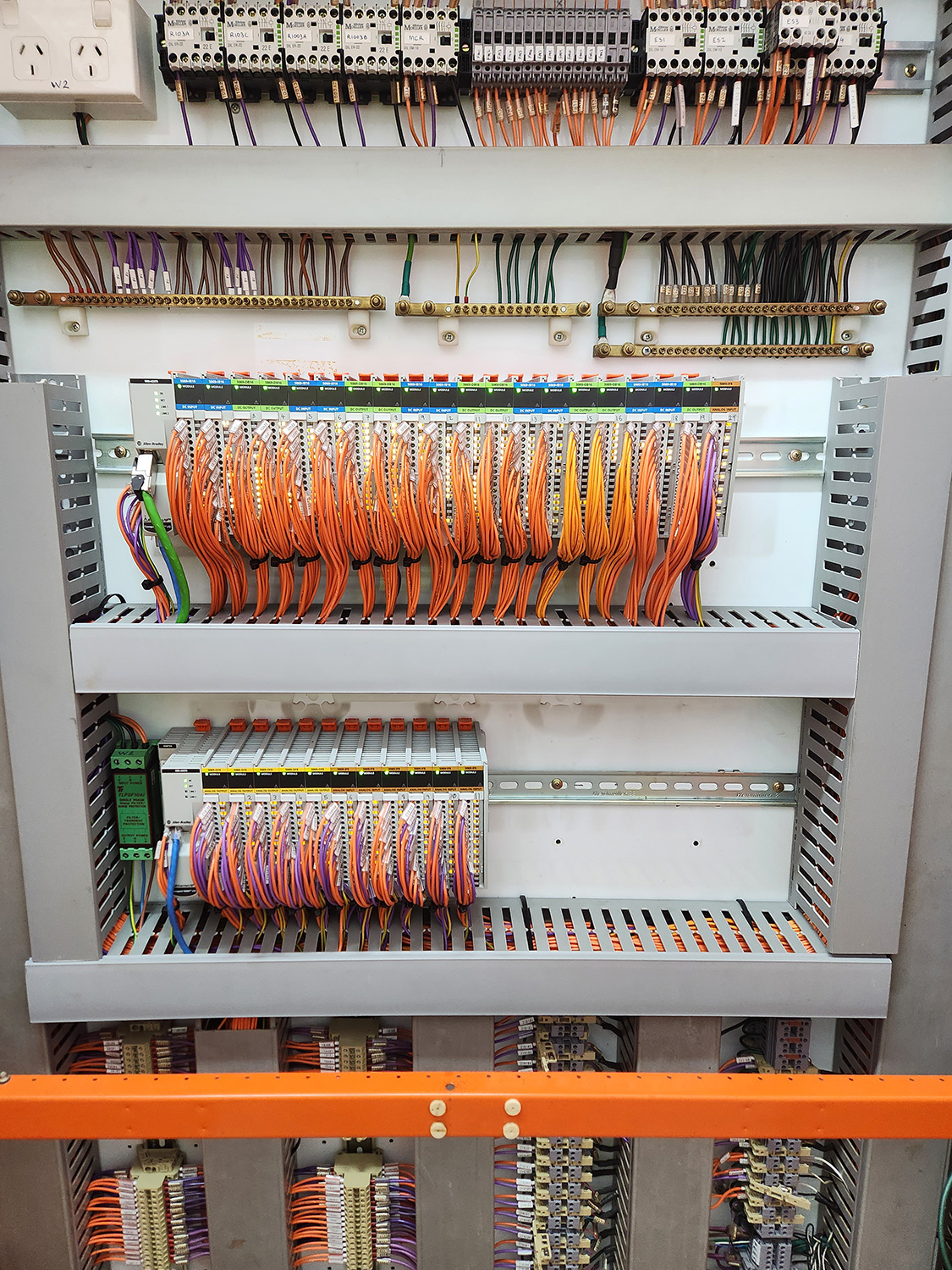

- To modernise operations and enhance safety, a full upgrade of the plant’s industrial control, SCADA (Supervisory Control and Data Acquisition) and PLC system was undertaken. The new system was carefully designed to reflect the interface of the existing SCADA layout, enabling staff to adapt quickly and confidently. The result is a more responsive, efficient and compliant control environment that supports both present-day needs and future developments.

- In response to changes in raw material composition and processing demands, significant upgrades were made to the soft-fats plant. These improvements were designed to double the plant’s capacity to handle higher throughput and maintain performance as volumes increased. The upgrades also improve process resilience and helps safeguard product quality and operational consistency.

- Additional high-speed, vertical disc separators were installed to handle the increased liquid load. The new units allowed the original separators to be used as online spares. The additional separator capacity has seen improvements in wastewater quality, reflecting Rendertech’s continued commitment to efficiency and sustainability in plant operations.

- Support was provided to re-establish the heat recovery loop, which uses reject energy from the render process to heat hot water in the main plant, reducing natural gas consumption and greenhouse gas emissions.

- The existing waste heat evaporator was replaced with a higher capacity unit to process waste from the render process and return it to product.

With a busy plant operating year-round, minimising disruption to day-to-day operations was essential. To meet tight time frames, the upgrade works were carefully planned and scheduled to coincide with existing holiday shutdowns. Rendertech worked closely with the O’Connor team to supervise and manage works on-site, completing the major upgrades within a focused nine-day period over Christmas and the remaining upgrades during the four-day Easter shutdown and weekends. This coordinated approach prevented disruption to operations.

A FOUNDATION FOR THE FUTURE

Megan Williams says the upgrade programme has given G&K a strong platform for the future and cemented an ongoing relationship with Rendertech. “Rendertech’s technical expertise, problem-solving ability, straightforward and honest approach, and proven track record make them a valuable partner for our business going forward.”

Equipment used

Rendertech Rendering Vessel