WASTEWATER TREATMENT EQUIPMENT

DUSKE DRYING SYSTEMS – Rotary Dryer

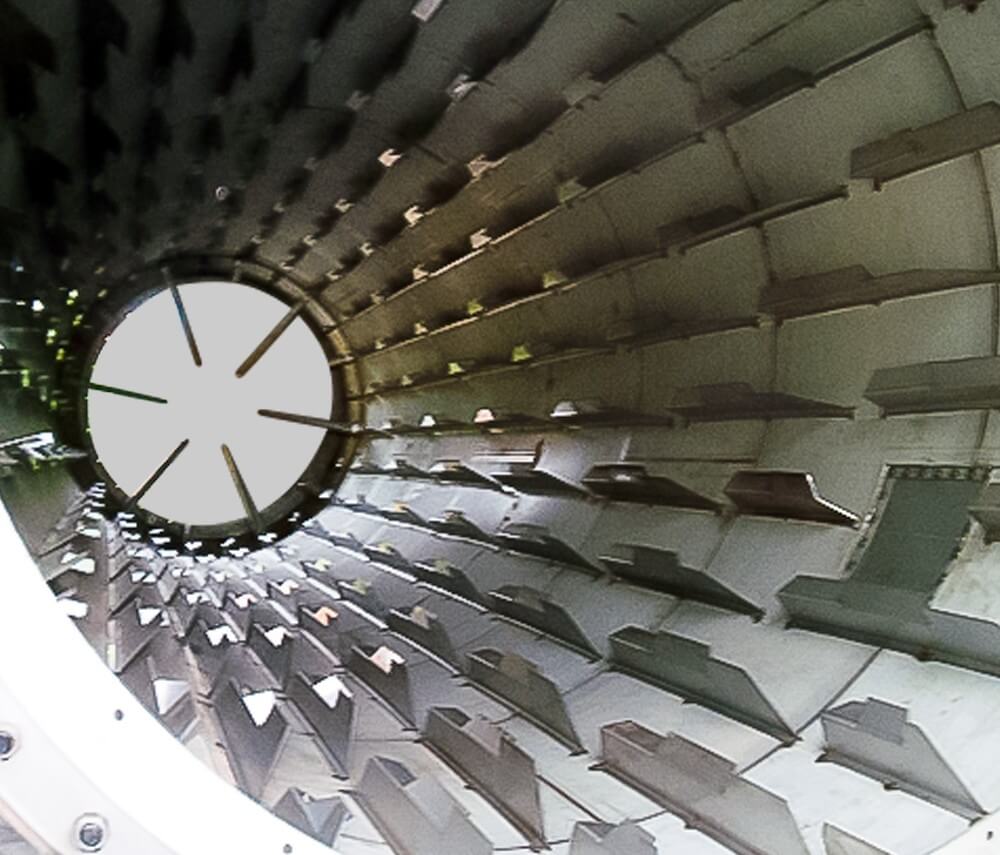

Direct-fired Rotary Dryers provide an economical and efficient solution for the drying of biomass and sludges. The wet material is conveyed into one end of the rotating drum, where it is dried as it is continuously cascaded through the hot air flow provided by a burner. Rendertech has supplied and supported Rotary Dryers in the Oceania region since 1988. We also offer local servicing and spare parts for Duske Drying Systems, now part of Uzelac Industries (USA).