Wastewater treatment and odour control

Rendertech designed and installed a modern wastewater treatment plant at Greenlea Premier Meats, a family-owned meat-processing plant just outside Hamilton. The new modern Dissolved Air Flotation (DAF) system sets the highest standards in contaminant capture and removal to reduce the company’s trade waste charges. And the integrated odour control system allows the plant to operate in a built-up area.

THE PROBLEM

Greenlea needed to upgrade their wastewater treatment plant to achieve a cleaner, more efficient decontamination process and resultant cost savings. They commissioned Rendertech engineers to carry out an initial cost–benefit analysis to confirm the viability of a DAF solution and its likely commercial payback. We carried out trials using our portable trial DAF plant to ascertain the best treatment solution and to confirm the likely contaminant reductions.

OUR SOLUTION

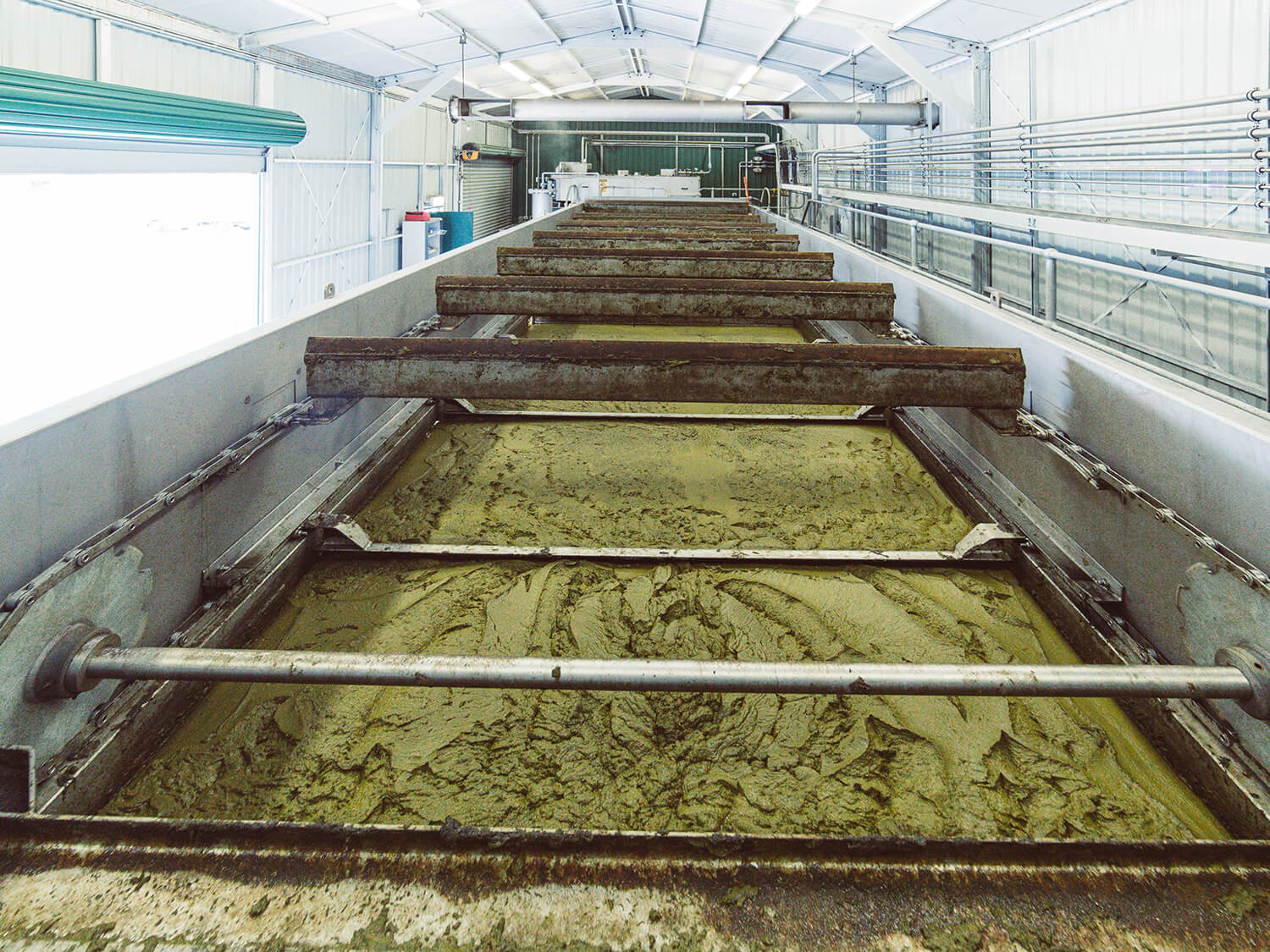

The Rendertech DAF system uses ‘chemical flotation’ whereby acid and polymer are automatically dosed into the wastewater prior to it entering the treatment tank (Flotator). This mixture coagulates and flocculates the fat and protein contaminants before air micro-bubbles float the solids to the surface, where they are scraped off as wet sludge. The treated wastewater is then discharged to the council’s sewage system, and the sludge goes through a Belt Filter Press to further reduce its volume.

Reduced wastewater charges

Chemical dosing increases the efficiency of the DAF process by removing a greater

percentage of contaminants. Consequently, Greenlea has enjoyed significant cost savings on their wastewater discharge to the council

sewage system due to the reduced contaminant load.

Effective odour containment

The DAF plant is housed in a purpose-built structure complete with

mechanical ventilation to maintain negative pressure inside, ensuring odours don’t escape. The ventilation air is then deodorised in a

Biofilter before discharge to atmosphere.

Equipment used

Dissolved Air Flotation plant, Filter Belt Press, Polymer Make-up Unit, Odour Control

System.