Low-temperature rendering plant

Rendertech has completed the design, manufacture and equipment installation for Alliance Group’s new $25 million Lorneville rendering plant.

Alliance’s facility near Invercargill is the largest sheep meat processing plant in New Zealand, with its rendering operation producing

about 50 tonnes of protein meal and 80 tonnes of tallow every day.

THE PROBLEM

Before the new plant was built in 2014, Alliance had been operating two ageing rendering plants to serve three processing sites. But their batch-rendering method – a high-temperature process – was burning a lot of energy, required a lot of labour and was ready for replacement.

OUR SOLUTION

We worked with Alliance to consolidate the legacy plants into one large, modern plant. We developed a complete solution based on the latest Rendertech Press Dewatering System, and matched this low-temperature, low-energy rendering process with our Contact Driers, Waste Heat Evaporator plant and Biofilter Odour Control. The greater energy-efficiency of the new plant has led to significant energy savings for Alliance, including:

- 9000 fewer tonnes of lignite used every year, and

- 1.5 million fewer kilowatt hours of electricity every year – enough to power 170 homes.

And the new plant produces almost zero wastewater or odour.

Higher quality products

The new plant has significantly increased Alliance’s productivity, meal quality and yields. They can now make protein meal at the higher

specification required by the aqua feed market. And they can process an additional 800 tonnes of raw material annually that previously went

to waste.

Reduced labour

The (mostly) automated plant operates around the clock, run by only four staff and a supervisor, whereas the previous two plants required a

total of 30 people to operate and maintain. The spare staff have been absorbed into the larger freezing works operation, which employs over

2000 people.

Equipment used

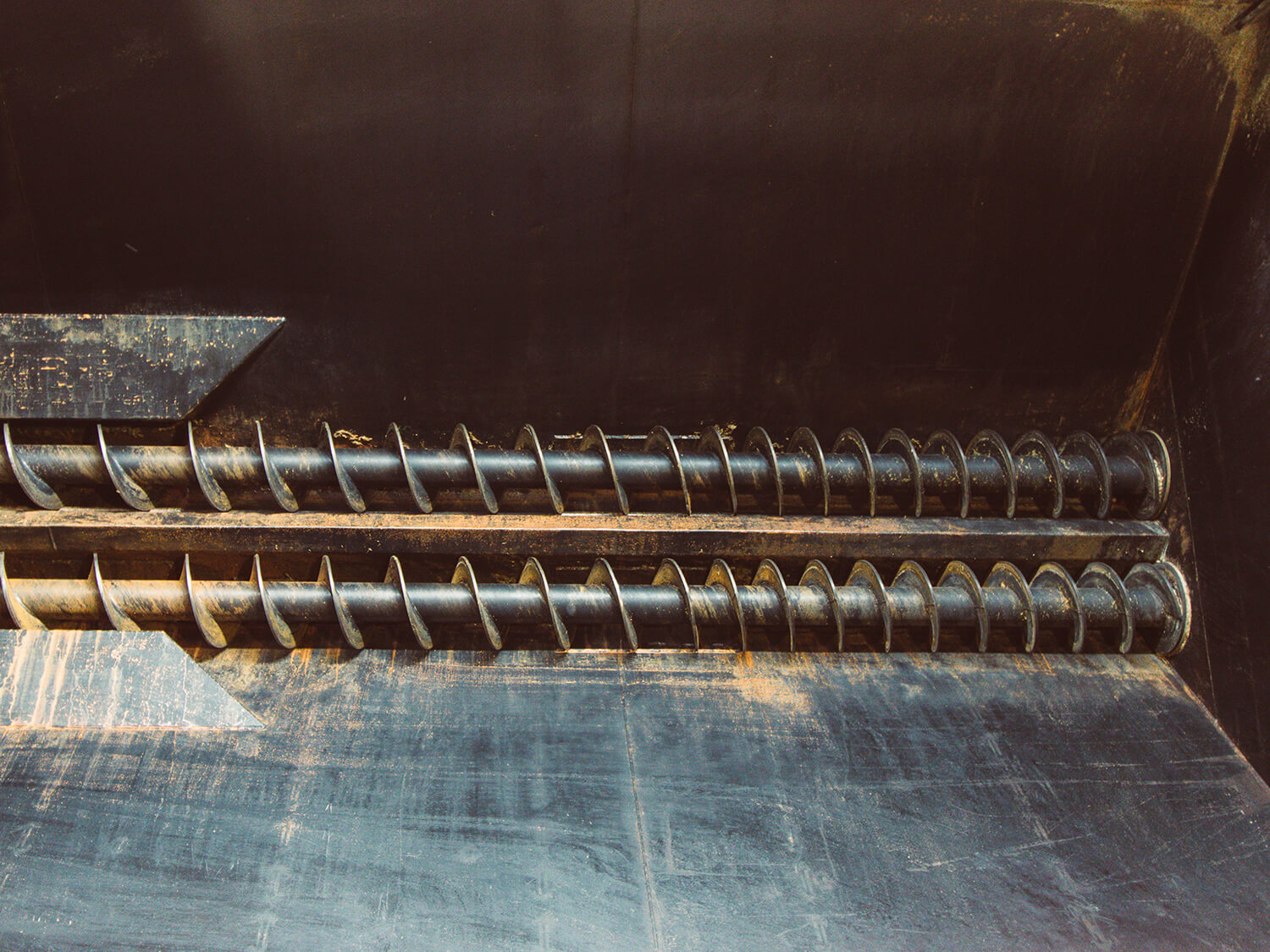

A complete rendering plant: Low Temperature Rendering, Press Dewatering System, Odour Control, Precooker, Twin Screw Press, Contact Driers,

Waste Heat Evaporator, Meal Plant.